In product development, timing can determine market success or failure. A delayed launch means lost revenue, ceded market share, and competitors gaining ground. For companies bringing plastic components to market through injection molding, the traditional path from concept to production has historically required patience, often months of tooling development before seeing the first molded part.

Rapid prototyping has fundamentally changed this equation. Manufacturers can now compress development timelines from months to weeks by leveraging faster tooling methods, advanced manufacturing technologies, and strategic process choices.

This article examines how rapid prototyping accelerates injection molding projects, the technologies and tooling strategies that make speed possible, and how to determine the right approach for different project requirements.

Understanding Rapid Prototyping in Injection Molding

Rapid prototyping in the context of injection molding encompasses several distinct but related approaches: creating prototype parts through additive manufacturing (3D printing), producing molded prototypes using rapid tooling, and employing bridge tooling strategies that transition projects from development to production.

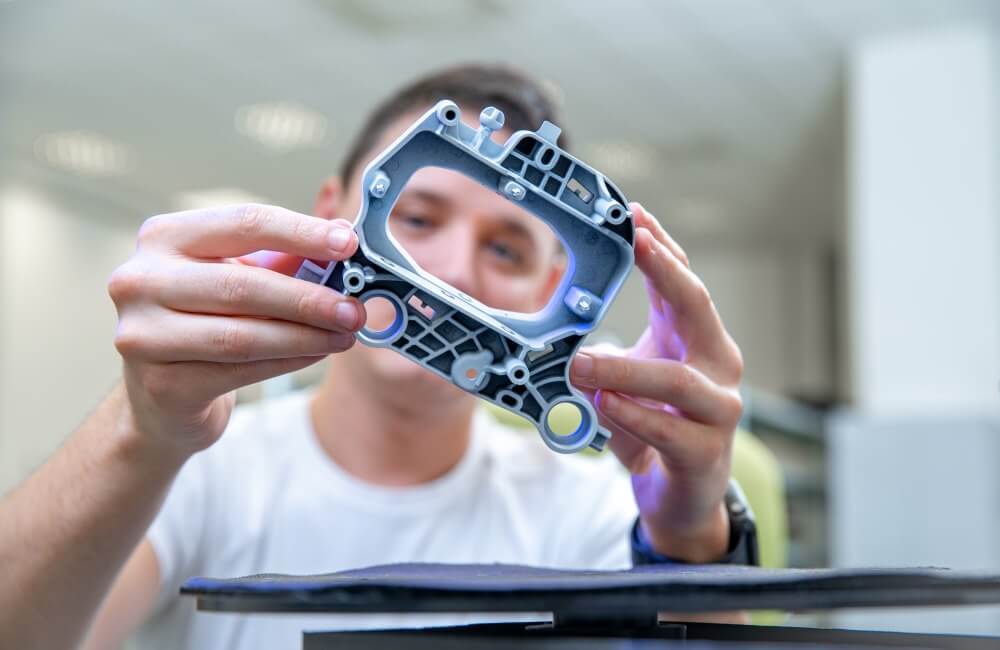

Unlike consumer product prototyping, where appearance models suffice, plastic injection molding prototypes often need to demonstrate functional performance in actual use conditions. Device housing must withstand sterilization cycles. An automotive component must survive thermal cycling and mechanical stress. A consumer electronics enclosure must meet drop test requirements. These functional demands make prototype injection molding using actual production materials and processes particularly valuable.

The fundamental advantage of rapid prototyping in injection molding is the ability to validate designs using production-representative parts before committing to expensive production tooling. This approach identifies design flaws, manufacturability issues, and performance problems when changes are still economical to implement.

Why Rapid Prototyping Matters

The financial case for rapid prototyping extends beyond simple time savings. Consider the cost implications at each stage of product development.

Traditional steel production molds require 35 to 60 business days to manufacture and that timeline assumes no design changes. If prototype testing reveals a geometry issue or dimensional problem, modifying a hardened steel tool can take an additional 20 business days and cost 10 times as much as the equivalent change in aluminum tooling. These delays cascade through project timelines, pushing launch dates and consuming engineering resources.

Rapid tooling approaches using aluminum molds compress initial tooling timelines to 15-25 business days. More importantly, design modifications can typically be implemented in approximately 5 business days at roughly one-tenth the cost of steel tool changes. This economic reality enables iterative design refinement that would be prohibitively expensive with production tooling.

Aluminum Tooling and Rapid Injection Molding Foundations

Aluminum molds are the workhorse technology for rapid injection-molding prototypes. The material properties of aluminum, softer than steel, excellent thermal conductivity, and easier machinability, translate directly into faster tooling production and more efficient molding cycles.

Lead Time Advantages

The time required to machine an aluminum mold is substantially less than that of steel due to the material’s machinability. Where a steel production mold might require two months of machining, heat treatment, and finishing, an equivalent aluminum tool can be ready in two to four weeks. Some rapid tooling providers deliver simple aluminum molds in as little as 7-10 days from final design release.

This acceleration stems from aluminum’s physical properties. The material machines faster, requires no heat treatment, and can achieve the required surface finishes with less polishing time. For projects where speed to first articles is critical, these differences compound into significant timeline advantages.

Cost Considerations

Initial investment in aluminum tooling typically runs one-quarter to one-half the cost of equivalent steel molds. An IBM study published in Moldmaking Technology compared identical aluminum and steel molds producing identical parts over five years and found that aluminum molds cost up to 50% less to build while producing higher-quality parts due to superior thermal control.

The cost advantage extends to design iterations. When prototype testing identifies needed changes, a rib that causes sink marks, a wall section that warps, or a snap fit that doesn’t engage properly, aluminum tools can be modified quickly and economically. This flexibility encourages the iterative refinement that produces optimized designs.

Thermal Performance

Aluminum’s thermal conductivity is approximately two to three times greater than that of steel. This property enables aluminum molds to heat and cool more uniformly and more quickly than their steel counterparts. The practical result is cycle times shorter than comparable steel tools, faster production of prototype quantities, and parts with better dimensional stability due to more uniform cooling.

For prototype runs where total quantity might be measured in hundreds or low thousands, these cycle time improvements may seem less significant than for high-volume production. However, faster cycles mean shorter machine time, lower costs per part, and quicker availability of parts for testing and validation.

Tool Life Considerations

Aluminum molds do have limitations. Typical tool life ranges from 10,000 to 25,000 parts, depending on part geometry, material being molded, and tool maintenance. This compares to 50,000-100,000 parts for P20 steel tools and potentially over one million parts for hardened steel production molds.

For prototyping and low-volume production, aluminum tool life is typically more than adequate. The decision point comes when projected lifetime volumes approach or exceed aluminum tool capabilities, at which point the economics favor steel tooling despite longer lead times and higher initial costs.

Integrating 3D Printing and Injection Molding

The relationship between 3D printing and injection molding has evolved from competition to complementarity. Each technology excels in different scenarios, and sophisticated product development programs leverage both strategically.

When to Use 3D Printing

Additive manufacturing excels in the earliest development stages when designs are still fluid and quantities are minimal. For one to ten parts needed quickly to evaluate form and basic fit, 3D printing delivers unmatched speed, often overnight or within days. No tooling investment is required, and design changes require only updating the CAD file.

3D printing also enables geometries impossible to mold, such as internal lattice structures or complex cooling channels. These capabilities make additive manufacturing valuable for creating functional prototypes that prove concepts even when the final production method will differ.

However, 3D printed parts differ from injection molded parts in important ways. Layer-by-layer construction creates anisotropic material properties; parts may be weaker in one direction than another. Surface finish, dimensional accuracy, and material options all differ from injection molding. For applications where these factors matter, injection molded prototypes provide more representative testing.

When to Use Prototype Injection Molding

Prototype injection molding becomes the preferred approach when functional testing demands production-representative parts. If prototype testing needs to validate material performance, dimensional consistency, or surface finish, molded parts provide data that printed parts cannot.

The crossover point where injection molding becomes more economical than 3D printing varies by part geometry and complexity. For standard parts, this transition typically occurs in the low hundreds to low thousands of units. For small, high-precision parts, the crossover may extend into tens of thousands, making 3D printing cost-effective for larger prototype quantities.

Rapid prototyping services that offer both technologies enable project teams to transition seamlessly as development progresses, starting with printed concept models, advancing to molded functional prototypes, and scaling to production volumes without changing manufacturing partners.

Bridge Tooling: Connecting Prototypes to Production

Bridge tooling represents a strategic middle ground between prototype and production tooling. These tools, typically aluminum or soft steel, enable production of meaningful quantities while permanent production tooling is being manufactured.

Use Cases for Bridge Tooling

Bridge tooling addresses several common scenarios in product development. When market demand is uncertain, bridge tools allow production of initial inventory without the full investment in production tooling. If testing or market feedback requires design modifications, changes can be implemented in bridge tools before committing to final production molds.

For products facing regulatory approval processes, bridge tooling enables production of validation and submission samples using production-intent materials and processes. Device companies particularly benefit from this capability, as FDA submissions require testing on parts manufactured using intended production methods and materials.

Bridge tools also provide supply chain insurance. If a production tool is damaged or a supplier faces capacity constraints, bridge tooling can maintain product availability while permanent solutions are implemented.

Transitioning from Bridge to Production

Effective bridge tooling strategies anticipate the transition to production tooling. Part designs validated in bridge tools should transfer directly to production molds without modification. Process parameters developed during bridge production inform production tool design and setup.

Some manufacturers structure bridge tooling agreements where the investment in bridge tools applies as credit toward production tooling. This approach reduces the total program cost while providing the flexibility and risk reduction that bridge tooling enables.

Design for Manufacturability in Rapid Prototyping

Rapid prototyping provides unique opportunities to validate design for manufacturability (DFM) before committing to production tooling. The iterative nature of prototype development enables testing of manufacturing assumptions and optimization of part designs for efficient production.

Early DFM Validation

Design-for-manufacturability principles, uniform wall thickness, appropriate draft angles, proper gate locations, and the elimination of undercuts affect both part quality and production economics. Prototype injection molding reveals whether theoretical DFM analyses translate to actual manufacturing performance.

Does the proposed gate location create acceptable flow patterns? Does the cooling design prevent warpage? Do the specified tolerances hold across production cycles? Prototype tooling answers these questions with actual molded parts, enabling design refinement before production tool fabrication begins.

Material Validation

Prototype injection molding also validates material selection decisions. While material data sheets provide property specifications, actual molded parts reveal how materials perform in specific geometries and applications.

Does the selected resin fill thin sections without short shots? Does it achieve the required surface finish? Does it maintain dimensional stability after molding? Testing prototype parts definitively answers these questions, avoiding costly material changes after production tooling has been cut.

Process Development

Beyond part design, prototype molding informs process development for production. The parameters that produce quality prototype parts, temperatures, pressures, cooling times, and cycle settings, provide starting points for production process development.

This knowledge transfer accelerates production startup. Rather than beginning process development from theoretical parameters, production teams start with validated settings that produced acceptable prototype parts, then optimize for production efficiency and consistency.

Selecting the Right Rapid Prototyping Approach

The optimal rapid prototyping strategy depends on project requirements, timeline constraints, quantity needs, and budget considerations. No single approach suits all situations.

Decision Framework

- For Concept Validation (1-10 parts, days to weeks): 3D printing provides the fastest path to physical models for form and fit evaluation. Use additive manufacturing when designs are still evolving and functional testing requirements are minimal.

- For Functional Prototyping (10-500 parts, weeks): Prototype injection molding with aluminum tooling delivers production-representative parts for functional testing. Use molded prototypes when material properties, dimensional accuracy, or surface finish affect testing validity.

- For Pilot Production (500-10,000 parts, weeks to months): Bridge tooling enables production of meaningful quantities for market testing, regulatory submission, or initial customer orders while production tooling is developed.

- For Production Preparation: Prototype tooling validates DFM assumptions and develops process parameters that transfer to production. Investment in prototype tooling reduces risk and accelerates production startup.

Partner Selection

Selecting a rapid prototyping partner capable of supporting projects through multiple development phases provides continuity advantages. When the same team produces early prototypes, bridge production, and eventually full-scale manufacturing, knowledge transfers efficiently between phases.

Look for partners offering both additive and molding capabilities, in-house tooling, quality systems appropriate to your industry requirements, and engineering support for DFM optimization. The right partner accelerates development not just through manufacturing speed but through the expertise they bring to design and process optimization.

Implementing Rapid Prototyping Effectively

Maximizing the value of rapid prototyping requires integrating it strategically into product development processes rather than treating it as a standalone service.

Start Early

Engage rapid prototyping capabilities at the earliest feasible point in development. The cost of changes increases exponentially as development progresses. A design modification that costs hundreds of dollars at the prototype stage might cost tens of thousands after production tooling is cut.

Early prototyping identifies issues when solutions are economical. A wall thickness that causes sink marks, a draft angle that prevents clean ejection, or a gate location that creates visible vestige marks; all these issues are better discovered in prototype tooling than production molds.

Plan for Iteration

Budget time and resources for multiple prototype iterations. Rarely does the first prototype perfectly satisfy all requirements. Planning for two or three design iterations helps prevent schedule surprises when refinements are necessary.

The economics of rapid tooling make iteration affordable. When aluminum tool modifications cost a fraction of steel tool changes and require days instead of weeks, iterative refinement becomes practical rather than prohibitive.

Capture Learning

Document the insights gained through prototype testing systematically. Material performance data, process parameters that produced quality parts, design modifications and their effects—this information has value beyond the immediate project.

Captured learning informs future projects, reduces development risk on subsequent programs, and builds organizational capability in design for injection molding. The investment in systematic documentation pays dividends across multiple product generations.

Next Steps

Rapid prototyping has transformed the economics and timelines of injection molding projects. What once required months of tooling development and significant financial commitment before seeing the first molded part can now be accomplished in weeks at a fraction of the cost.

The technologies enabling this acceleration, such as aluminum rapid tooling, strategic use of 3D printing, and bridge tooling approaches, each address specific needs within the development process. Used strategically, they compress timelines, reduce development costs, and improve the quality of final designs through iterative refinement.

For companies developing plastic components, rapid prototyping capabilities have become essential to competitive product development. The ability to quickly produce functional prototypes, validate designs in production-representative materials, and iterate efficiently separates successful launches from delayed disappointments.

Whether your project requires early concept models, functional prototypes for testing, or bridge production while production tooling is developed, the right rapid prototyping strategy can dramatically accelerate your path to market. Contact our team to discuss how rapid prototyping can speed your next injection molding project from concept to production-ready design.

Learn more about KS Plastics and explore our manufacturing facilities in California and Mexico. Our experienced engineers provide guidance from initial prototyping through full-scale production.