When manufacturers face the challenge of producing millions of identical plastic parts with consistent quality, tight tolerances, and competitive pricing, the conversation inevitably turns to multi-cavity molds. These sophisticated tooling solutions have transformed the economics of high-volume plastic manufacturing, enabling dramatic reductions in per-part costs while multiplying production throughput. But like any manufacturing decision, choosing multi-cavity tooling involves careful consideration of trade-offs between upfront investment, production efficiency, and long-term operational costs.

This guide examines the advantages and limitations of multi-cavity molds for large production runs, providing manufacturing engineers and procurement professionals with the technical insights needed to make informed tooling decisions.

Understanding Multi-Cavity Molds

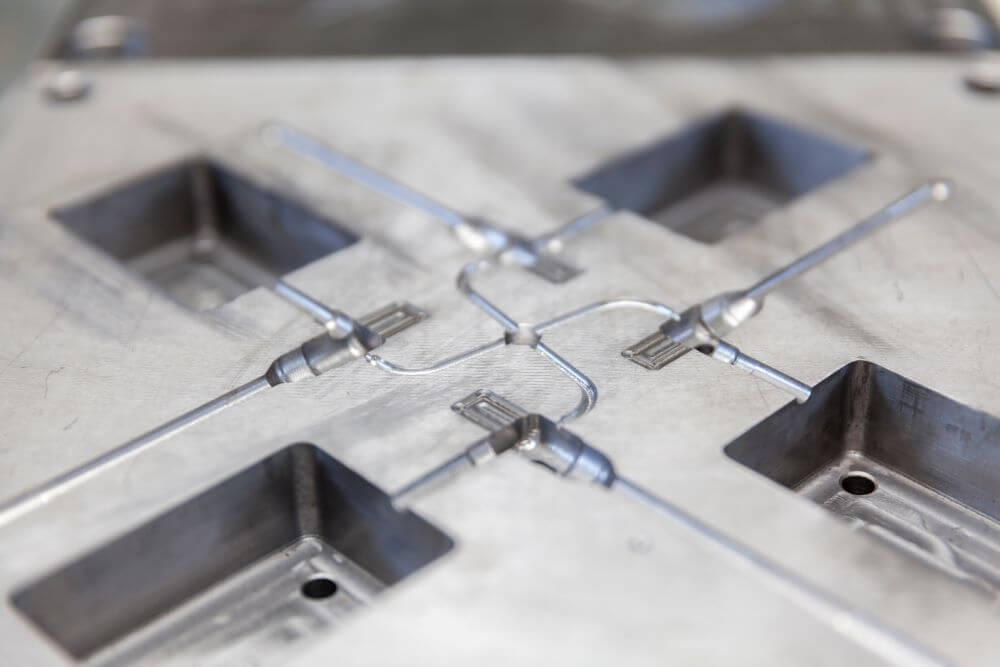

A multi-cavity mold is a precision-engineered tool containing two or more identical cavities within a single mold base, allowing simultaneous production of multiple parts in every injection cycle. While single-cavity molds produce one component per cycle, multi-cavity configurations can manufacture anywhere from two to 128 or more identical parts with each shot of molten plastic.

The mathematics behind multi-cavity efficiency are compelling. If a single-cavity mold produces one part every 30 seconds, an eight-cavity mold produces eight parts in that same timeframe—effectively multiplying output by a factor of eight without requiring additional machine time, operators, or facility space. For a 1,000-piece order, a single-cavity mold requires 1,000 injection cycles, while a 10-cavity mold completes the same order in just 100 cycles.

Multi-cavity molds should not be confused with family molds, which also contain multiple cavities but produce different component geometries in a single cycle. Multi-cavity molds focus exclusively on producing identical parts, leveraging symmetrical cavity layouts to ensure uniform filling and consistent quality across every impression.

The Advantages of Multi-Cavity Molds

Dramatically Increased Production Throughput

The most significant advantage of multi-cavity molding is the exponential increase in production capacity. A properly designed 16-cavity mold can produce 16 parts in the time a single-cavity tool produces one. This multiplication effect becomes increasingly valuable as production volumes grow into the hundreds of thousands or millions of units.

For manufacturers facing tight delivery schedules, multi-cavity tooling can mean the difference between a 12-week lead time and a three-week delivery. When customers require 500,000 parts on an aggressive timeline, producing 16 parts per cycle instead of one fundamentally changes production planning capabilities and market responsiveness.

Reduced Per-Part Manufacturing Costs

Per-part costs drop dramatically when machine time, labor, and overhead are distributed across multiple parts per cycle. A single press operator monitoring an eight-cavity mold generates eight times the output of the same operator running single-cavity tooling. This labor efficiency compounds with every additional cavity.

According to industry analysis, projects requiring more than 500,000 parts annually almost always justify high-cavity tooling investments, assuming part geometry and size allow for efficient cavity layout. The economics become even more favorable for simpler components—consumer products like bottle caps, closures, and packaging components routinely utilize molds with 32, 64, or even 128 cavities.

Optimized Machine Utilization

A single injection molding machine equipped with a high-cavity mold can achieve output that would otherwise require multiple machines, presses, and operators. This translates to lower facility costs, reduced energy consumption, and simplified production management. Rather than coordinating production across multiple machines with separate process parameters and quality controls, manufacturers can concentrate high-volume production on optimally configured equipment.

Improved Batch Consistency

When all parts originate from the same mold during a single injection cycle, they experience identical processing conditions—the same material batch, temperature profile, pressure curves, and cooling rates. This inherent consistency often results in tighter dimensional control and more uniform mechanical properties across production batches compared to parts produced sequentially from single-cavity tooling over extended production runs.

Multi-cavity molds designed with balanced runner systems and optimized cooling ensure that each cavity receives equivalent material flow and thermal conditions, minimizing cavity-to-cavity variation throughout the tool’s production life.

Long-Term Cost Efficiency

While multi-cavity molds require higher upfront tooling investment, the total cost of ownership often favors multi-cavity approaches for high-volume applications. Return on investment calculations must consider amortized tooling costs, piece-part production costs, machine utilization, labor efficiency, and facility overhead.

Break-even analysis typically favors multi-cavity tooling when annual part demand exceeds 100,000 units and product design remains stable for long-term production. The higher initial investment pays dividends through millions of production cycles, often achieving payback within the first year of full production for high-volume programs.

The Challenges of Multi-Cavity Molds

Substantially Higher Tooling Investment

The most significant barrier to multi-cavity adoption is the substantial upfront tooling cost. While a simple single-cavity mold might cost $10,000 to $15,000, comparable multi-cavity configurations can exceed $100,000 depending on cavity count, part complexity, and material requirements.

Multi-cavity molds require more steel, longer machining time, additional engineering for balanced runner systems and cooling circuits, and more complex quality validation. Each additional cavity multiplies precision-machining requirements while demanding increasingly sophisticated engineering to maintain uniform performance across all impressions.

Complex Engineering Requirements

Designing multi-cavity molds introduces engineering challenges that don’t exist in single-cavity applications. The runner system design represents perhaps the most critical challenge—runners must deliver equal amounts of molten plastic at identical pressures and temperatures to each cavity, regardless of their position in the mold.

Uneven flow distribution causes inconsistent filling, which manifests as dimensional variations, short shots in some cavities, or overpacking in others. Achieving true balance requires careful calculation of runner lengths, cross-sectional areas, and gate sizes—often aided by mold flow simulation software to predict and correct imbalances before cutting steel.

Cooling system design becomes equally critical in multi-cavity configurations. Cooling typically represents the longest phase of the injection molding cycle, and any thermal imbalance between cavities causes differential shrinkage, warpage, and dimensional inconsistencies. Modern multi-cavity molds incorporate optimized cooling circuits that ensure uniform heat removal from all cavities, sometimes utilizing conformal cooling channels that follow part contours for enhanced thermal efficiency.

Extended Lead Times for Tooling

Multi-cavity molds require significantly more time to design, engineer, and manufacture than single-cavity alternatives. The increased complexity of runner balancing, cooling optimization, and cavity layout demands more engineering hours before machining begins. The actual machining process takes longer due to the multiple identical cavities that must be cut to identical specifications.

For manufacturers facing urgent production timelines, this extended tooling lead time can be a significant disadvantage. Single-cavity molds can often be fabricated and validated in a fraction of the time, enabling faster production ramp-up for new product launches or emergency capacity needs.

Increased Maintenance Complexity

More cavities mean more surfaces to clean, inspect, and maintain. Multi-cavity molds require more rigorous preventive maintenance programs to ensure all cavities continue producing parts within specification. If wear develops differently across cavities—which inevitably occurs over millions of cycles—individual cavity maintenance or refurbishment becomes necessary to maintain uniform quality.

Maintenance procedures that take minutes on single-cavity tooling may require hours on high-cavity molds. When problems occur, troubleshooting becomes more complex because issues must be isolated to specific cavities, runner sections, or cooling circuits.

Quality Control Challenges

Maintaining consistent quality across all cavities throughout the tool’s production life represents the fundamental challenge of multi-cavity manufacturing. How do you guarantee that the millionth part from cavity 16 maintains the same dimensions, surface finish, and performance characteristics as the first part from cavity one?

The answer lies in scientific molding principles and rigorous quality systems. Process monitoring and automation provide real-time assurance that each cycle meets established parameters.

Pressure sensors, temperature monitoring, and position feedback ensure consistent results, with systems that automatically make corrections or stop production when parameters drift outside acceptable ranges.

Statistical process control programs must account for cavity-to-cavity variation, tracking individual cavity performance over time. When specific cavities begin trending toward specification limits, targeted maintenance can address developing issues before they result in rejected parts.

Limited Design Flexibility

Once a multi-cavity mold is manufactured, modifying the part design becomes significantly more challenging and expensive than with single-cavity tooling. Any design change must be implemented across all cavities, multiplying modification costs and lead times.

This limitation makes multi-cavity molds unsuitable for products still undergoing development or frequent engineering changes. Many manufacturers adopt a progressive strategy—starting with single-cavity molds during product development, then transitioning to multi-cavity tooling only after the design is fully validated and stable for long-term production.

Higher Machine Requirements

Multi-cavity molds require injection molding machines with sufficient clamping force and shot capacity to fill all cavities simultaneously. A mold that operates comfortably on a 100-ton press in single-cavity configuration may require a 500-ton or larger machine when scaled to eight or 16 cavities.

Larger machines carry higher operating costs—greater energy consumption, more expensive maintenance, and higher hourly rates that partially offset per-part cost reductions from increased cavitation. This machine capacity requirement must be factored into total cost analysis, particularly when existing equipment may not accommodate high-cavity configurations.

When Multi-Cavity Molds Make Sense

Multi-cavity tooling delivers maximum value under specific production conditions:

- High-Volume, Stable Designs: Products with annual demand exceeding 100,000 units and stable designs that won’t require modification during the tool’s production life are ideal candidates. The higher upfront investment pays back through millions of cycles when part geometry remains constant.

- Simple to Moderate Part Complexity: Parts with straightforward geometries that don’t require complex side actions, lifters, or collapsible cores scale more efficiently to multi-cavity configurations. Complex mechanisms multiply across cavities, dramatically increasing tooling costs and maintenance complexity.

- Smaller Part Sizes: Smaller parts allow more cavities within a given mold size, maximizing the efficiency gains from multi-cavity approaches. Large parts may be limited to lower cavity counts due to machine capacity constraints and mold size limitations.

- Consistent Material Requirements: Products that use standard engineering thermoplastics with well-characterized processing windows are easier to balance across multiple cavities than specialty materials with narrow processing tolerances.

When Single-Cavity Molds Remain Preferable

Single-cavity tooling offers advantages in several scenarios:

- Product Development and Prototyping: During development phases when design changes are expected, single-cavity molds offer faster modification turnaround and lower change costs.

- Low to Medium Production Volumes: For annual volumes below 50,000 units, single-cavity tooling often delivers better total economics when considering both tooling investment and production costs.

- Complex Part Geometries: Highly intricate parts requiring extensive side actions, precision mechanisms, or tight tolerance control benefit from the focused attention and simplified processing of single-cavity approaches.

- Tight Timeline Requirements: When production must begin quickly, single-cavity molds can be designed, manufactured, and validated faster than multi-cavity alternatives, enabling earlier production start.

Best Practices for Multi-Cavity Implementation

Manufacturers considering multi-cavity tooling should follow established practices to maximize success:

- Invest in Simulation: Mold flow analysis software helps predict and prevent filling imbalances, thermal variations, and potential defects before cutting steel. Early simulation investment prevents costly tooling modifications later.

- Specify Quality Materials: High-volume molds destined for multi-million piece runs must be constructed from hardened tool steels such as H-13 or S-136 that can withstand extreme pressures and temperatures while maintaining dimensional stability throughout their production life.

- Design Robust Cooling Systems: Incorporate optimized cooling circuits that ensure uniform temperature distribution across all cavities. Consider conformal cooling for complex geometries requiring enhanced thermal management.

- Plan for Maintenance: Establish comprehensive preventive maintenance programs from day one. Track individual cavity performance through statistical process control to identify developing issues before they impact quality.

- Partner with Experienced Toolmakers: Multi-cavity mold design and manufacturing require specialized expertise that not all tooling suppliers possess. Select partners with demonstrated multi-cavity experience and the precision manufacturing capabilities to execute complex designs.

Making the Right Choice

Multi-cavity molds represent a powerful manufacturing strategy for achieving economies of scale in high-volume plastic production. When properly engineered and executed, these sophisticated tools can dramatically reduce per-part costs while multiplying production throughput. However, the decision to invest in multi-cavity tooling requires careful analysis of production volumes, part complexity, design stability, and total cost of ownership.

The most successful implementations balance the efficiency gains of high-cavity configurations against the increased complexity, tooling investment, and maintenance requirements. By understanding both the advantages and limitations of multi-cavity approaches, manufacturers can make informed decisions that optimize their production economics and competitive positioning.

For manufacturers exploring multi-cavity options for their high-volume programs, working with an experienced injection molding partner provides access to the tooling expertise, process engineering knowledge, and quality systems necessary to realize the full potential of multi-cavity production.

Looking to optimize your injection molding production? Contact KS Plastics to discuss your high-volume manufacturing requirements and explore how our precision tooling and scientific molding expertise can help you achieve your production goals.